- Head Office:

- C.so Roma 131/A

28883 Gravellona Toce (VB)

- Working hours:

- Monday through Friday:

8:00-12:00 / 14:00-18:00

Vocation to Total Quality

Quality

The company guarantees compliance with the agreed tolerances thanks to large investments in equipment and staff training.

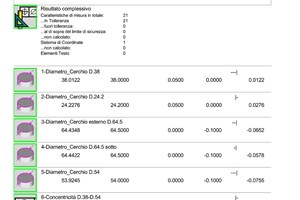

For dimensional testing there is an air-conditioned room available with a Zeiss O-Inspect 322 CMM, with optical detection, probing and form scanning.

For surface control we have a Mahr M400 microprofilmometer / roughness tester, for general purpose a profile projector, altimeters, internal / external micrometers, concentricity banquet with tailstocks, and a large fleet of fixed and mobile gauges, for threads and diameters.

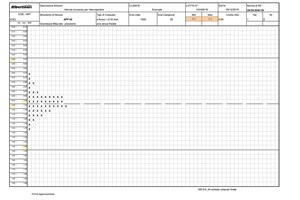

We are competent in the field of process capability, PPAP and similar approval process, and we develop and manage process control plans through management own software.

Thanks to advanced instrumentation and compliance with the metrological traceability chain, we can issue dimensional test certificates for products

CERTIFICATED ISO 9001 SINCE 1998

Digital Pressure and Flux Gauge

Digital Spring tester

Tridimensional Meauserement Machine Zeiss

A PRESTIGIOUS CMM TACTILE / OPTICAL PERMIT TO CHECK DIMENSIONS, FORMS, GEOMETRY OF WORKED PARTS

Roughness Meter