We are pleased to announce the installation of our new photovoltaic system on the roof of our facility. This new installation will allow us to use solar energy as a renewable and sustainable source of power. Green energy is an important alternative to fossil fuels, as it reduces greenhouse gas emissions and air pollution. We are proud to do our part in protecting the environment and promoting a sustainable way of life.

- Head Office:

- C.so Roma 131/A

28883 Gravellona Toce (VB)

- Working hours:

- Monday through Friday:

8:00-12:00 / 14:00-18:00

A little long story

Story

A little bit of history

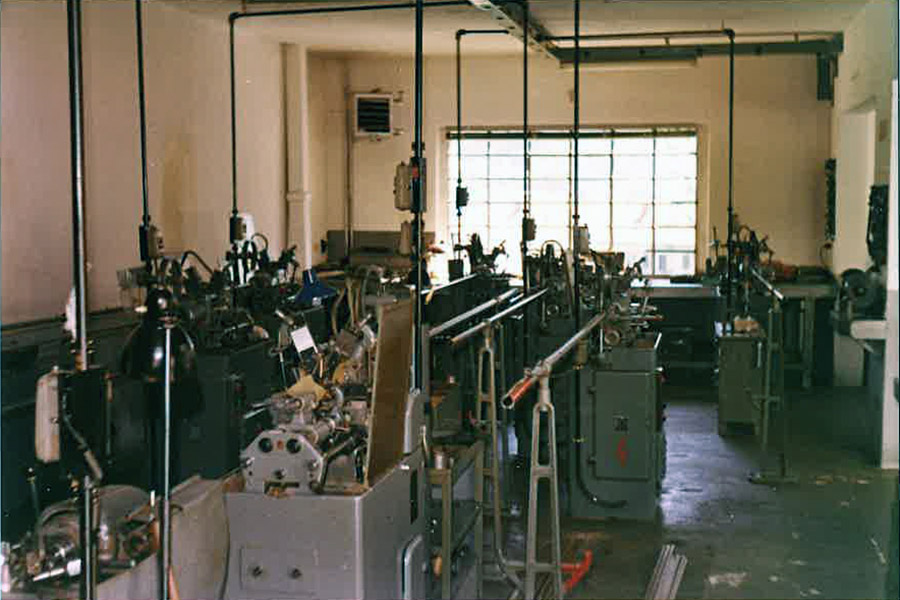

Albertinari is a family name that since the end of the 1800s has been linked to metallurgy, since the founder Giovanni, put his skills as a blacksmith at the service of nascent railway lines, furnish hardware for the Simplon line and tunnel, on the Sesto Calende bridge, of which he collaborated to produce and riveting the rivets, and later, the last of eight children, Guerrino Remo, as soon as the Second World War ended, he took up the baton together with his wife Afra putting himself to the test with the first automatic lathes in Crusinallo trying to satisfy the needs of the nascent district of houseware in Cusio zone and in particular of the Coffee Maker field, of which it becomes the undisputed reference point for safety valves. From its inception the company has distinguished itself for a production cycle almost entirely carried out in-house, with the highest possible degree of verticalization, which allows us to offer competitive prices and to maintain quality control, management, and why not, retain the know-how inside company.

Significant stages of development

- 1948 Start of production in Crusinallo plant

- In 1970 we builds the first transfer for valve assembly

- In 1982 the business moves to a new and more spacious factory in Gravellona Toce

- In 1994 the first multi-spindle lathe is acquired

- In 1997 the first numerically-controlled sliding head lathe is acquired.

- In 1998 ISO 9001 certification is achieved

- In 2001 the first automatic valve testing machine

- In 2004 development of the SAI management software is started in Microsoft Access

- In 2006 the first Bi-Turret Biglia lathe is acquired

- In 2010 the first robotised lathe has arrived: a Takamaz X180

- In 2013 the centralized cooling system is started for the liquid refrigerants in turnery

- In 2014 the ZEISS O-I322 3D measuring machine is acquired

- In 2016 the factory is expanded, bringing the operating surface to about 1500 square meters

- In 2017 the 4.0 integration of the CNCs with the rest of the plant is completed

- In 2017 an Okuma MACTURN 250W lathe is acquired

- At the end of 2018 we grew up: we changed our business name: from Snc to Srl

- In 2019 a robotized island is started with a 5-axis milling machine

- In 2022 a 130KW photovoltaic system is installed on the roof of the factory

- In 2022 a new multi-spindle CNC lathe is launched

Albertinari Today

The current corporate structure of ALBERTINARI srl sees the participation of the fourth generation of the family, to guarantee the continuity of the company in a sub-supply market characterized by high instability.

The production processes are organized with a current staff of 15 people. Particular attention is paid to the training of operators, carried out both internally and at external companies. The involvement and motivation of the operators is considered a fundamental element of a dynamic and harmonious work environment, the very low turnover of the personnel is an indication of the correct personnel management policies.