Our company Albertinari srl, active in Italy since 1948, is world leader in production of small safety valves.

The attention to details and the continuous improvement of products and company performance, never excessive prices in spite of the expensive investments, have contributed to build a strong corporate reputation as supplier of safety devices.

for the world of manufacturing companies, always looking for reliable suppliers, ALBERTINARI SRL is proposing as extremely solid partner; and to guarantee a profitable relationship we bring more than seventy years of technical experience in the field of precision mechanical processing, and specifically in realization of small safety valves for an infinite number of uses: coffee makers, coffee machines, pressure cookers , sterilizers, food processing, automotive, earthmoving, pneumatics, hydraulics, lubrication, and much more.

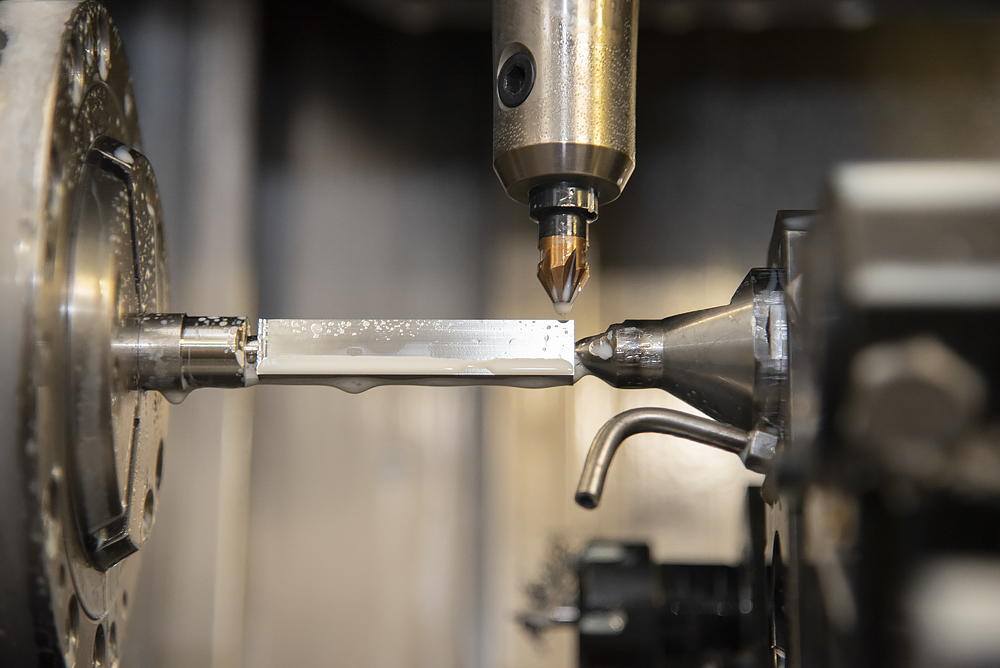

To the production of valves we add the precision mechanical processing from customer design, thanks to the presence of extremely advanced production and testing machinery.